Art Byrne, one of the most successful CEO’s in history with more business turnarounds as both an executive and in Private Equity than most will ever achieve.

If you’re a chairman struggling to consistently increase your enterprise value, lend an ear to Art Byrne – “What does it take to Lead a Lean Turnaround?”

6 Myths of Product Development

Many companies have not tapped the full potential their product development process, because their management thinking has not evolved as quickly as the technology for execution:

they still approach the Highly variable information-generating work of product development as if it were like manufacturing, failing to recognize it is profoundly different.

Details why lean product development works and applying manufacturing principles to product development does not:

Progressive management identifies untapped talent and cultivates it.

NBA.com

Traditional management vets candidates by what happened in the past instead of what they’re capable of, and loses the talent they have available to be deployed.

Progressive management identifies untapped talent and cultivates it.

engineering stds, late change submissions, & HR facilitating management agreement

(from LEI, David Verble article, follow link)

Examples of the confusion caused by unclear standards in engineering, late change submissions, and HR facilitating management agreement to support training by David Verble.

https://www.lean.org/the-lean-post/articles/no-standard-no-problem-not-really-its-a-big-problem

key points:

“Most companies have KPIs (Key Performance Indicators), but these are generally operational output or end-of-process measures. They also are “lagging indicators” because they show the result of the work performed but not how smoothly and efficiently the work is flowing in the process–unless they fail to achieve output KPIs. With no process or work standards, those completing the process have no way to evaluate how they are performing or where to focus problem-solving when there are problems in output results.”

“Without a standard, there is no way to see what improvements need to be made to improve performance or see the impact of changes that have been made. It’s hard to improve on a base of chaos.”

1) you can’t just drop responsibility for something on people. You must make sure it works with their situation and priorities if you expect them to follow through on it.

2) you have to understand the broader context of what else is going in the company when you ask for agreement to a plan.

MRI following primary repair of the anterior cruciate ligament

Primary repair of the anterior cruciate ligament (ACL) is being performed increasingly in the treatment of acute proximal ACL ruptures. Advantages of ACL repair over surgical reconstruction with a tendon graft include preservation of the anatomy and proprioceptive function of the native ACL, and therefore, faster rehabilitation. The addition of an internal brace protects the repair during ACL healing and can increase the success rate of the procedure.

Given this evolution of ACL surgical treatment, radiologists should be familiar with the new repair techniques and their appearances on postoperative imaging.

In this article, we describe two different surgical techniques for primary ACL repair, dynamic intraligamentary stabilisation and internal brace ligament augmentation, and provide an overview of the normal and abnormal appearances after this type of repair at magnetic resonance imaging (MRI) follow-up.

May 06, 2019

https://www.clinicalradiologyonline.net/article/S0009-9260%2819%2930157-6/fulltext

Although Canada is about a decade behind adopting current orthopedics with respect to these types regenerative medicine procedures, radiologists can prepare in advance.

The Canadian radiologist who interpreted my regrown ACL MRI did so incorrectly, however when reviewed by those familiar with current procedures it was exactly the mottled appearance expected for that period of time.

City of Calgary’s newly elected mayor could adopt continuous improvement

What kind of results would this yield? see below

Here are some results from a city the practiced excellence in governance for about five years: Cape Coral, Florida

A previous write up explained by 2007 the return on the invested consulting dollars was 14 times – counting only hard dollar savings.

In July 2009 the city report included this sample of results:

Team reduced the time to obtain a permit for construction 61% from 21 days to 8 days.

54% reduction in time required to hire a firefighter went from 66 days to 30 days.

Lot mowing time was reduced 63% from 52 days to 19 days to mow the grass once and send a notice of violation to the property owner.

The cycle time for first reviews in Site Plan Development initially decreased to 5 days from 28 days. The time currently is 8 days.

18 events in seven City departments resulting in about $2 million in cost savings and/or cost avoidance. The goal in every event is to increase productivity and reduce cost without sacrificing quality and the service to our citizens.”

- Lean Government Coordinator for the City of Cape Coral: Ms. Roop

I save the results in files when I find them, however they change their websites and occasionally the previous links do not work. I cannot find whether Cape Coral continued generating results beyond 2012.

Cities & governments that continue employing lean thinking achieve ongoing consistent results for constituents, improve services while reduce lead times and costs; Calgary is capable of this.

Here’s an example of a results report at the state level – it can be applied at any organization or government level – this is just a better example of results in a wide variety of government services. Unfortunately the link is not working, just going to copy & paste; formatting is off but read through you’ll get the picture

Continuous Improvement Minnesota

2010/2011 Results

Agency

Division/

Unit

Fiscal

Year

Tools

Used

Results Achieved

Department of Administration

Real Estate and Construction Services

2010

Kaizen

event

Improved real estate leasing process time by 67 percent.

Fleet and Surplus Services (FSS)

2010

Kaizen

event

Reduced time to enrol fleet vehicles in M5 be 69 percent.

Department of Agriculture

Dairy and Food

Licensing Division

2011

Kaizen

event

Improved customer service through an 80 percent reduction in the amount of time necessary for reviewing and issuing license documentation to customers.

Lab Services Division

2010

Kaizen

event

Improved operations through a 33 percent reduction in elapsed time and a 25 percent reduction in task time for the “short path” lab results reporting, and a 68 percent reduction in elapsed time and task time for “long path” lab results reporting, with potential staff time-savings of 2.2 FTE per year.

Dairy and Food

Licensing Division

2010

Kaizen

event

Reduced the time for an establishment to get a license by 99.8 percent.

Department of Commerce

Consumer and Industry Services

2010

Kaizen

event

Reduced average time to process an insurance product file by 65 percent.

Department of Corrections

Shakopee Facility

2011

Kaizen

event

Used evidence based practices to prioritize and balance offender work assignments and self-development opportunities while maintaining offender programming schedule.

Information Technology

2011

Kaizen

event

Improved customer service processes with FootPrints service ticket system for internal and external staff.

Willow River/Moose Lake facilities

2011

Kaizen

event

Reduced and leveled out inmake movement to reduce congestion, reduce staffing costs, and improve safety.

Faribault Facility

2011

Kaizen

event

Increased staff productivity, reduced traffic through truck gate, and reduced offender pull-outs and down time.

Stillwater Facility

2011

Kaizen

event

Improved the efficiency of the facility movement schedule resulting in increased facility security, increased offender production hours, and maintained facility programming.

Shakopee Women's Facility

2011

Kaizen

event

Reduced the amount of staff overtime, refined current overtime monitoring process, and identified potential cost reductions in the future.

Red Wing facility

2011

Kaizen

event

Improved business operations by developing a staff schedule that maximizes staff resources, increases programming time and maintains staff safety.

Togo Facility

2011

Kaizen

event

Improved operations by developing a staff schedule that maximizes programming time, coordinates schedule among units and defines core schedule requirements.

Shakopee Facility

2011

Kaizen

event

Improved operations by streamlining intake and transportation processes, resulting in more effective use of staff and other resources.

Shakopee Facility –

Work Release Program

2011

Kaizen

event

Improved operations by streamlining work release processes to maximize the length of eligible offenders’ stay in the program.

Willow River and

Moose Lake Facilities

2011

Kaizen

event

Improved internal operations by completing 100 percent of mandatory staff trainings with the fewest scheduling tasks and by reducing instances requiring excessive communication.

Lino Lakes facility

2011

Kaizen

event

Improved service by ensuring that 100 percent of offender releases occur on the correct date through the creation of a one-cycle work flow that eliminates duplication of effort and ensures the appropriate use of staff resources on priority tasks.

Offender Classification

2011

Kaizen

event

Improved service by refining the process that ensures consistent application of the offender classification system.

Faribault Facility

2011

Kaizen

event

Improved service by increasing the number of mandated offenders enrolled in the literacy program; reduce the number of offenders called out from literacy classes and align literacy program schedule with that of other DOC facilities.

Togo Facility

2010

Kaizen

event

Improved operations by developing a staff schedule that maximizes programming time, coordinates schedule among units and defines core schedule requirements.

St. Cloud Correctional Facility

2010

Kaizen

event

Simplified staffing schedule by reducing the number of officer start times from 17 to eight in order to balance the needs of both the institution and the staff.

Willow River/Moose Lake Correctional Facility

2010

Kaizen

event

Created new staffing and training schedules that more adequately balance training requirements and coverage of officer posts.

Lino Lakes

2010

Kaizen

event

Improved workplace safety.

Department of Employment and Economic Development

Trade Adjustment Assistance

2011

Kaizen

event

Redesigned financial process in preparation for new statewide financial software. Reduced tasks by 41 percent, waits by 55 percent, handoffs by 71 percent, and total process time by 47 percent.

Minneapolis WorkForce Center/Dislocated Worker

2011

Kaizen

event

Reduced time for determining eligibility, standardized forms, client folders and process steps for a 77 percent reduction in process time and 29 percent reduction in task time.

Unemployment

Insurance Division

2011

Kaizen

event

Improved customer service by creating a standard process for applicants to follow; reduced the amount of time applicants need to access specialized employ-ment services.

Unemployment

Insurance Division

2011

Kaizen

event

Improved customer service through a 50 percent reduction in phone inquiry response time.

Unemployment

Insurance Division

2011

Kaizen

event

Improved customer service by reducing the amount of time needed to resolve an extended unemployment coverage request to an average of one day from the previous 14-25 days.

Workforce Centers

2011

Kaizen

event

Improved workflow and customer service by redesigning customer service areas, improving signage and improving the allocation of technical resources.

State Services for the Blind

2011

Kaizen

event

Reduced the elapsed time by 71%, and the task time by 42% to provide an assessment audio technology requirements for clients seeking employment services

Financial Management

2011

2P – Process Preparation

Developed a new process that will allow for the efficient interface between the DEED Workforce 1 work tracking software, and the State’s new financial tracking system, SWIFT

Workforce Development/Trade Adjustment Assistance

2010

Kaizen

event

Developed a standard process for Trade Adjustment Assistance (TAA) requests and will create TAA program policies for consistent and accurate responses. The new process reduces total process time by 53 percent and task time by 70 percent.

Unemployment

Insurance & Workforce Development

2010

Kaizen

event

Established standard process for referrals from Re-employment & Eligibility Assessment (REA) to Re-employment & Eligibility Services (RES).

Minnesota Investment Fund

2010

Kaizen

event

Reduced process time for disbursing community development grants by 93 percent.

Department of Health

Vital Record Unit

2011

Kaizen

event

Standardized birth and death certificate application process, reduce tasks by 40 percent, waits by 79 percent, handoffs by 50 percent, and total process time by 96 percent.

User Support Services

2011

Kaizen

event

Standardized video conference scheduling tools and processes to meet increasing demand, save time and maintain high quality of work for a 22 percent reduction in tasks and 25 percent reduction in handoffs.

Commissioner's Office

2011

Kaizen

event

Created a standardized emergency communication response process to be utilized within the agency and with partner agencies/stakeholders.

Licensing and Certification Division

2011

Kaizen

event

Reduced the elapsed time to schedule and capture nursing home surveys by 34% and save approximately 3 FTEs of staff time.

Commissioner's Office

2010

Kaizen

event

Utilize a standard electronic system to process and track inquiries and empower key staff to make response decisions. The new process will lead to savings in paper, supplies and staff time and be 67 percent faster than the old process.

Licensed Home Care

2010

Kaizen

event

Reduced time for home care license pre and post survey process by 62 percent.

Department of Human Services

Contracts Division

2011

Kaizen

event

Improved business operations by reducing the elapsed time for processing a professional/technical contract by 40 percent and reducing the amount of staff time necessary for processing a contract by 30 percent.

TSS Testing

2011

Kaizen

event

Documented the testing process, eliminated unnecessary duplication and testing, and detected quality issues earlier in the process while mainting high quality standards. Reduced process time by 46 percent and wait time by 50 percent.

Central Imaging Unit

2011

Kaizen

event

Improved business operations and availability of information through a 58 percent reduction in the time required for preparing and imaging health care enrollment documents.

Medical Assistance Program

2011

Kaizen

event

Improved customer service through a 37 percent reduction in the time needed for determining eligibility on requests for medical assistance (MA) payment of long-term care (LTC), from an average of 87 days to 55 days.

Adoptions Record Unit

2011

Kaizen

event

Reduced the elapsed time to process a scanned adoption record file by 30%. Reduced the amount of task time required by 3 FTE per year. Will save thousands of dollars in paper and printing costs.

Human Resources

2010

Kaizen

event

Developed a consistent hiring process for central office, SOS, and MSOP. The new process will reduce the elapsed time of the bidder fill process by 57 percent and no bidder fill process by 40 percent.

Health Care Administration

2010

Kaizen

event

Improved process time for gathering MMIS estimates by 78.5 percent.

Health Care Administration

2010

Kaizen

event

Streamlined the bill analysis and fiscal note processes, created a bill prioritization system, updated forms to match the new process, created standard work and a central repository for all bill analyses and fiscal notes.

Department of Military Affairs

MN Army National Guard

2010

Kaizen

event

Reduced the time it takes to capture vehicle usage and distribute vehicles by 80 percent.

MN Army National Guard

2010

Kaizen

event

Reduced Enlisted Personnel System (EPS) packet process time by 64 percent.

Department of Natural

Resources

Office of Management and Budget

2011

Kaizen

event

Improved internal operations through a 75 percent reduction in the amount of time needed to request and receive legislative authorization, from an average of 12 weeks to an average of three weeks.

Forest Planning Unit

2010

Kaizen

event

Improved business operations and resource management through an 80 percent reduction in the amount of time needed to develop and adopt forest management plans, from an average of three years to eight months.

Department of Public Safety

Driver and Vehicle Services

2011

Kaizen

event

Improved customer service through a 70 percent reduction in processing time for expedited title transfers.

Human Resources

2010

Kaizen

event

Reduced hiring process time by over 50 percent.

Bureau of Criminal Apprehension

2010

Process

redesign

Redesigned process for providing customers with permission and connectivity to BCA services.

Department of Revenue

Return Mail Processing Unit

2011

Kaizen

event

Reduced the amount of re-sent mail by 60 percent, reduce the elapsed time to re-send mail by 75 percent, and reduce costs of re-sending mail estimated at $80,000 per year.

Department of Transportation

2011

Kaizen

event

Standardized training announcement process, created announcement template, developed training calendar for a 57 percent reduction in task time, a 33 percent reduction in wait time, and a 38 percent reduction in total time for the training announcement process.

Office of Civil Rights

2011

Kaizen

event

Improved service through an 80 percent reduction in the amount of time needed to review and clear Disadvantaged Business Enterprise contract applications, from an average of 63 days to an average of 12 days.

Materials Management

2011

Kaizen

event

Improved business operations by standardizing the materials acquisition process and reducing the cycle time from an average of 18 days to 15 days for each contract.

Financial Management

2011

Kaizen

event

Improved business information by ensuring that accurate, clear and consistent financial data is avail-able to agency managers and leaders as quickly as possible.

IT Development

2011

Kaizen

event

Improved service by streamlining the IT development process, reducing lead time by 45 percent and leading to quicker project assessment, improved customer satisfaction and reduced staff time commitment.

Operations Division

2010

Kaizen

event

A 68% reduction in elapsed time for vacancies filled by bid and 69% reduction in elapsed time for vacancies filled competitively. The new process also includes a one-stop shop for vacancy related information and enhancements to the Strategic Staffing Plan.

Platting Process

2010

Kaizen

event

Reduced time spent developing plats by 36 percent. Eliminated handoffs and reduced total wait time by four weeks.

Geometric Design

Support Unit

2010

Kaizen

event

Reduced the time it takes to process design exceptions by 85 percent by establishing response timelines and enhancing training.

EDMS unit

2010

Kaizen

event

Reduced the Electronic Document Management System process time by 56 percent.

Department of Veterans Affairs

Hastings Veterans Home

2011

Kaizen event/

root cause analysis

Developed a more efficient morning routine for meeting patient needs at the Hastings facility.

State Soldiers

Assistance program

2010

Kaizen

event

Improved customer service through a 70 percent reduction in task time and a 58 percent reduction in wait time in the process for reviewing and approving financial benefits for qualified veterans seeking assistance.

Minneapolis Veterans Homes

2010

Kaizen

event

Created standard of work for resident mealtimes and staff break times to make process more resident centered with an emphasis on teamwork and enhanced communication.

Minneapolis Veterans Homes

2010

Kaizen

event

Created a streamlined admissions process that is easier, faster and more understandable for families, residents and staff.

Hastings Veterans

Homes

2010

Kaizen

event

Created a more efficient referral and lab process.

Minnesota State Colleges and Universities

Office of the Chancellor

2011

Kaizen

event

Reduced the process time for filling vacancies needing classification by 54% and vacancies not needing classification by 62%.

Metropolitan State University

Student Admissions

2011

Kaizen

event

Reduced the elapsed time to evaluate transfer credits and determine eligibility for admissions by 75 percent.

Registrar's office

2010

Kaizen

event

Improved class scheduling process time by 61 percent.

Pollution Control Agency

Communications Unit

2011

Kaizen

event

Developed a streamlined, standard process for making updates to the PCA website.

Surface Waters

2010

Kaizen

event

Redesigned the water quality assessment process.

http://www.lean.state.mn.us/LEAN_pages/results.html

Chinese Manufacturers Ask: ‘How Can Americans Still Afford to Buy from Us?’

Excellent write up repeating the pitfalls from basing decisions on ‘piece-price’ and failing to factor actual total cost of ownership – with some perspective from the international business community laughing at how North Americans miss this. It doesn’t seem to matter how often this is communicated, CFO’s and purchasing managers keep using inaccurate costs to base decisions on. However now that shipping costs are 10x higher, finance/accounting, purchasing will incur a greater loss for missing this – learn to calculate your total cost of ownership.

Key points from article:

“The cost benefit to manufacturing in China just isn’t there anymore.”

“in the U.S., purchasing organizations are primarily fixed on obtaining the lowest “piece-price,” pretty much regardless of other factors.

When asked “why,” I responded that reduction in material was the primary metric used to judge and reward purchasing managers.

I was then again asked, “why?” My response was that material variance is a primary focus when U.S. corporate CFOs report their quarterly financial results to stock analysts where, by the way, total cost is seldom—if ever—mentioned.

I had to explain this several times, as most of the attendees were incredulous to the fact.”

“Most suppliers are geographically close to their customers” – *a JIT practice – “and so are more closely integrated with them than their western counterparts.”

“Total cost,” not “piece-price” is what is measured.

“Despite most of the attending companies having current or past business relations with American customers, most were completely unaware of how Americans viewed performance in its purchasing function.

It didn’t make sense to them, but did generate a few laughs”

“if honest total cost metrics are employed, the cost benefit to sourcing in China just isn’t there anymore.”

Harry Moser, Reshoring Initiative CEO, set up a total cost calculator CFO's can use to learn their Total Cost of Ownership Estimator available here https://www.reshorenow.org/tco-estimator

I’ve used this to calculate actual cost comparisons at more than one company and it typically is more economical to source locally – which also reduces sourcing from region typically supplying product high in defects, which increases lead times when you have to reorder to replace defective stock and let the customer know you won’t be on time. Local sourcing also reduces distance & associated lead times, a direct driver of sales and bottom line results.

*I can't recall a business that knew their actual cost of offshoring, do you know yours?

Hire Leaders for What They Can Do, Not What They Have Done

Another excellent article worth reading in its entirety:

https://hbr.org/2019/08/hire-leaders-for-what-they-can-do-not-what-they-have-done

Mapping the Frontier of Knowledge - Juan Enriquez

Highly underrated, this is one of the most insightful talks available. Few people provide the macro perspective Juan Enriquez does. I have a lot of notes on this, it is dense.

It is posted here:

https://longnow.org/seminars/02007/oct/12/mapping-the-frontier-of-knowledge

and on youtube here:

https://www.youtube.com/watch?v=GLCagm6nqJQ

however Squarespace cannot figure out why it won’t embed, a problem they have not resolved for over a year, despite confirming it’s internal on their end. Will update as they resolve, hopefully it doesn’t take an additional year.

3 Questions to Help Confirm a Company is Practicing Lean Product Development:

1. What is your new product introduction cadence?

What is the % on time, and percentage on budget? If not consistently on time & on budget, what is the gap you have to close?

Photo: conventional chaos vs lean

credit: Dantar P. Oosterwall,

The Lean Machine: How Harley-Davidson Drove Top-Line Growth and Profitability with Revolutionary Lean Product Development, p.106

2. Where are you applying set based concurrent engineering?

Photo: Denso trade off curves

Credit: Allen C. Ward, Durward K. Sobek,

Lead Product and Process Development, 2nd ed. p.172

3. Where are you using trade off curves in development?

Where is design/engineering creating trade off curves to supply reusable knowledge to accelerate product development?

Some questions I provided an institutional board member to help them validate whether their investment is applying lean business strategy.

If not, it is worth more than traditional financial analysis is capable of revealing.

70% of Costs can be Influenced by the Product Design Shadow

graphic credit: Sandy Munro

Business often focuses on areas with the biggest bottom line contribution.

Where is it?

The biggest opportunity to impact these costs can be in product design where decisions lock in the on-going costs.

Traditional cost accounting misses this.

You don’t have to.

Lean Product and Process Development in Canada?

Looking for someone else practicing Lean Product and Process Development in Canada.

Likely in southern Ontario.

Please message me

Toyota Replacing Robots with Humans

*It’s the thinking that is important

I originally read

At Toyota, The Automation Is Human-Powered in 2017. An AME conversation this morning reminded me of it:

“While the rest of the auto industry increasingly uses robots in manufacturing, Toyota has taken a contrarian stance by accentuating human craftsmanship.”

it also contains some info stating historically there is a direct correlation between productivity growth, which robots should naturally contribute to, and job creation using ATM's as an example (see chart).

Two more from 2014 I found, and there few more in addition to this, but the same thinking applies.

Results from one of these articles:

“Toyota has eliminated about 10% of material-related waste from building crankshafts at Honsha. Kawai said the aim is to apply those savings to the next-generation Prius hybrid.”

“We cannot simply depend on the machines that only repeat the same task over and over again,” Kawai said. “To be the master of the machine, you have to have the knowledge and the skills to teach the machine.”

“Fully automated machines don’t evolve on their own; Mechanization itself doesn’t harm, but sticking to a specific mechanization may lead to omission of kaizen and improvement.”

https://financialpost.com/transportation/toyota-robots-humans

This one from PEOPLE POWER in Bloomberg, my notes, link below:

Toyota is becoming more efficient by replacing robots with humans

“Car makers have embraced automation and replaced humans with robots for years. But Toyota is deliberately taking a step backward and replacing automated machines in some factories in Japan and creating heavily manual production lines staffed with humans”

“It’s an unconventional choice for a Japanese company. Japan has by far the most industrial robots of any country, with an estimated 309,400 (pdf p. 17.) Only South Korea has a higher ratio of robots to humans.”

Toyota’s latest strategy has two main aspects:

“First, it wants to make sure that workers truly understand the work they’re doing instead of feeding parts into machines and being helpless when one breaks down.”

“Second, it wants to figure out ways to make processes higher quality and more efficient in the long run.”

“The company worries that automation means it has too many average workers and not enough craftsmen and masters.”

“So far, people taking back work done by robots at over 100 workspaces reduced waste in crankshaft production by 10%, and helped shorten the production line. Others improved axle production and cut costs for chassis parts.”

“We cannot simply depend on the machines that only repeat the same task over and over again. To be the master of the machine, you have to have the knowledge and the skills to teach the machine.”

“The manual lines are a refocus on “Kaizen,” or continuous improvement, and “Monozukuri,” which is essentially the art of making things well. It’s a re-commitment to management ideas behind the decades old Toyota Production System.”

“Machines are great at doing things quickly and at low cost. But people—especially ones with the experience of performing tasks themselves—bring craftsmanship, insight into process design, and consistency of quality. Toyota has found that the race to reduce the human element can end up making processes less efficient.”

https://www.bloomberg.com/news/articles/2014-04-06/humans-replacing-robots-herald-toyota-s-vision-of-future

Friction-Killing Tactics To Make Products More Seamless

One of the best articles I’ve read in awhile. From First Round (that writes a lot of great business content) by Amazon’s Kintan Brahmbhatt. I’m not going to summarize it, read the whole thing. Twice.

FRICTION — anything that gets in the way of a customer and a task

https://review.firstround.com/amazons-friction-killing-tactics-to-make-products-more-seamless

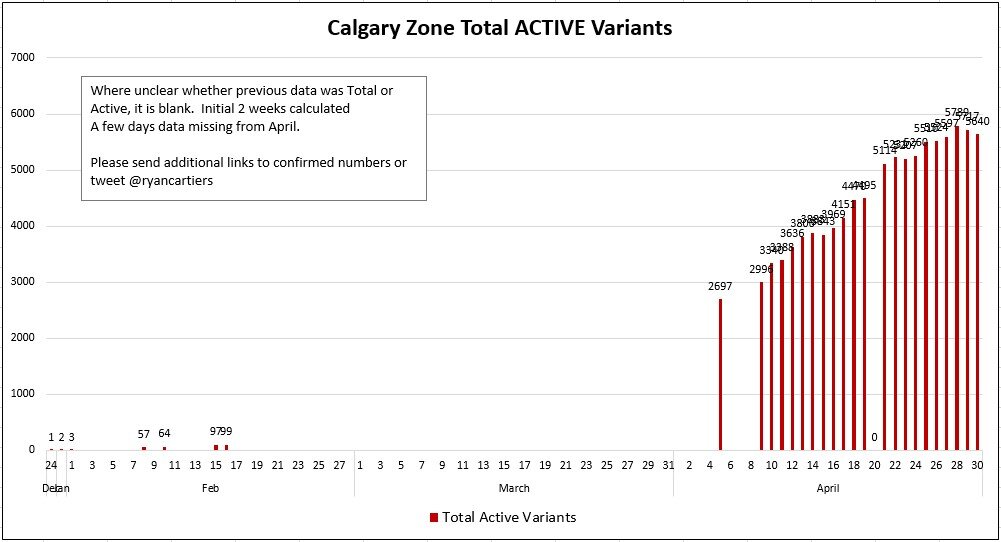

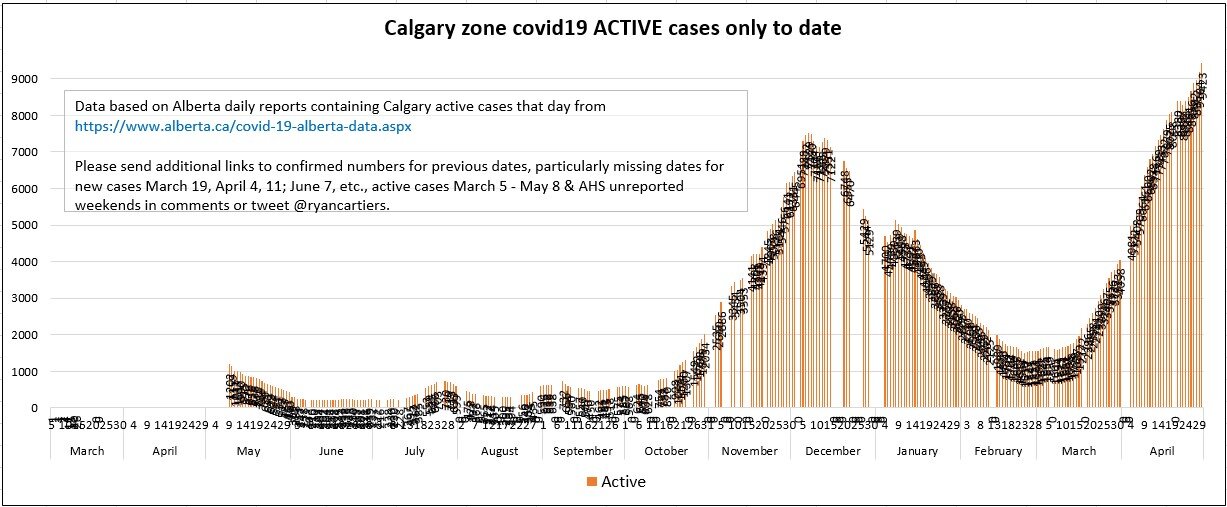

Calgary zone Covid-19 Case & Variants update May - AHS admits numbers inaccurate

Alberta Health Services admits on their website they are only screening a sample of positive cases and to “Interpret Case Numbers with Caution”

in other words, AHS screening of positive cases is incomplete therefore ‘don't trust our numbers’.

Again AHS decided not to respond to inquiry sent via twitter.

Due to this, it is of questionable value to continue creating the monthly Calgary zone case & variant trend chart updates based on information AHS admits is lacking integrity.

With Alberta Health’s recommendation to not trust their May 2021 numbers, this may be the final covid update I post, the 1 chart I have not seen them display - Calgary Zone Total ACTIVE Variants - based on their daily published data I could find. I did not see it reported separately or track hence the Feb - Mar gap, however I was able to calculate the initial period.

*Note how fast the reported case #’s dropped, and how variant case #’s did not become the dominant strain as predicted, or as seen in other countries. It is unclear whether this is due to the inaccurate case counts AHS admitted, increasing vaccination rates or people spending more time outdoors.

Given the large # of service workers available receiving CERB payments, there could be an effort by AHS to tap these resources to help make tracing phone calls or case count. This would also reduce pulling trained nurses from the front line to man the phone lines for tracing - and then claim a shortage of nurses.

India variant identified in Alberta May 3.

Schools opened this week though, and the province plans to reopen instead of follow the proven zero covid strategy (details in April covid link) that has consistently resulted in covid free / restriction free countries/provinces.

Regarding opening - closing restriction criteria; previous searches have not turned up with a result nor have my inquiries been answered, however the above was recently released. It appears it is based on hospitalizations & vaccination rates.

I’ve been wanting to do an analysis to see if previous opening - closing restriction criteria were based on case numbers. Restrictions were communicated as being in place to reduce healthcare overwhelm, which based on wait times was over capacity in many was prior to the corona virus.

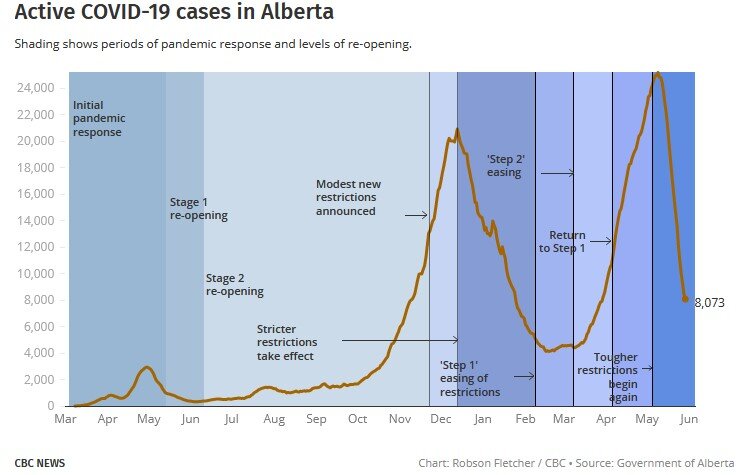

This graphic from CBC allowed me to pull the numbers I’ve been tracking and do the analysis:

Alberta Covid-19 Restriction & Reopening Timeline from CBC

May 13 2020 - Stage 1 reopen around 1000 cases & dropping

Jun 11 2020 – stage 2 reopen around 372 cases & increasing

Jul 18 2020 – cases continue climbing past 1000 (would this not trigger Stage 1?)

Nov 23 2020 – after cases climb for 5 months up over 13,000 modest new restriction announced

Dec 13 2020 – after cases further climb over 20,000 stricter restrictions announced

Feb 8 2021 – even though cases have only dropped to 5000, and variants have been identified, this is ignored in lieu of ‘step 1’ easing of restriction (previous trigger 1000 cases)

Feb 23 2021 – at the 2 week mark after easing of restrictions – the corona virus incubation period – cases predictably start increasing again

Mar 8 2021 – ‘step 2’ easing, followed by predictable exponential increase

Apr 6 2021 – instead of addressing the exponential increase, it is allowed to increase above 11,000 before return to ‘step 1’

May 5 2021 – after allowing the largest case climb to date, over 24,300, restrictions similar to the initial pandemic response (which crested at 3,000 cases) are finally returned

May 9 2021 – Alberta hits 25,185 and cases start dropping, however this is only 4 days after restrictions instead of the 2 week incubation period, leaving two explanations:

transmission slowed due to other factors towards the end of April (may include vaccination; people outdoors due to weather)

the numbers are incorrect, plausible as Alberta Health reported on their website that screening is incomplete (“only a sample”) and not to rely on their numbers (“interpret with caution”), therefore it is unclear what the actual case counts are

open to other explanations, please share

A cases hospitalized timeline may help determine whether that was what the openings - closing were based on. There is no evidence it was case #’s.

Predictably, restrictions reduce cases, however based on AHS’s recommendation not to rely on their numbers, it is unknown if cases are actually under 9000.

No Satisfaction at Toyota

Great article by FastCompany, key points:

It restructures a little bit every work shift.

10 hours in painting. Robots did much of the work, then as now, but they were supplied with paint through long hoses from storage tanks. “If we were painting a car red, before we could paint the next car white, we had to stop, flush the red paint out of the lines and the applicator tip, and reload the next color,” Georgetown literally threw away 30% of the pricey car paint it bought, cleaning it out of equipment and supply hoses when switching colors.

Cars now spend 8 hours in paint, instead of 10. The paint shop at any moment holds 25% fewer cars than it used to. Wasted paint? Practically zero. What used to require 100 gallons now takes 70.

Not only does Georgetown use less paint, it also buys less cleaning solvent and has dramatically reduced disposal costs for both. Together with new programming to make the robots paint more quickly, has increased the efficiency of its car-wash-sized paint booths from 33 cars an hour to 50.

“We’re getting the same volume with two booths that we used to get with three, so we shut down one of the booths.” If you want to trim your energy bill, try unplugging an oven big enough to bake 25 cars. Workers dismantled Top Coat Booth C, leaving the open floor space available for some future task.

shutting down Top Coat Booth C liberated a handful of maintenance engineers–who turned their attention to accelerating the next round of changes. Success, in that way, becomes the platform for further improvement. By the end of this year, Buckner and his team hope to have cut almost in half the amount of floor space the paint shop needs–all while continuing to paint 2,000 cars a day.

tenaciously competitive quality

Lean / continuous improvement have been around for more than a quarter-century.

You outflank them next decade. They just don’t realize it.

Toyota wasn’t just another workplace but a different way of thinking about work.

Contrasted to the American business culture of not admitting, or even discussing, problems in settings like meetings.

please talk to us about your problems so we can all work on them together.'”

improvement is much more realistic, much more human

improving something starts after understanding the standard – understanding how we do it now. If you don’t understand what you’re trying to improve, how do you know that your suggestion is an improvement?”

How come the checkout lines at Wal-Mart never get shorter?

How come the customer service of your cell-phone company never improves, year after year? How come my PC gets harder to operate with each software upgrade?

doing it in every single department, every single day. They’re doing it on their own

You simply can’t lose interest in it, shrug, and give up – any more than you can lose interest in your own future.

Doing the task and doing the task better become one and the same thing

Job Interviews - How to Spot Toxic Management

"48% of managers hadn’t received any management training in the previous 12 months and 33% of companies did not offer any training at all." How much does your business offer?

“Bad management can originate in a structure that does not allow better behaviour. A “toxic” manager is rarely alone in a company. They are tolerated by the organization, if not supported outright. These kinds of practices can be found at other levels within the organization, the bad manager being only one active piece of a harmful system.” - some executives protect employees and ostracize those who - in the best interests of the company - point out the damaging behaviour.

“to identify gangrenous companies, it is worth looking at staff turnover” - one of the reasons to work with executives understanding this & absenteeism early in acquisition assessment or turnarounds

https://www.welcometothejungle.com/en/articles/job-interviews-how-to-spot-toxic-management

12th Ebola Virus Outbreak Trend May 3

May 3

DRC health ministry declared the end of the country's 12th Ebola outbreak, given that 42 days have passed with no new cases since the last patient was released from treatment.

Guinea

- situation still isn't stable; some contacts lost to follow up; 1 confirmed case remaining in the community, which raises the risk of further spread

Calgary zone Covid-19 Case & Variants update Apr 2021

Alberta Health added Total Variants Active to their data:

Total ACTIVE variant cases

Cumulative Variant cases

New cases

Active cases

Total confirmed

Searched to find reopening criteria as the reopening threshold is not maintained between Phase 1 & 2 as demonstrated:

Mar 1, 2021 - announce Phase 2 reopen 1560 cases (is the threshold below 1600 cases?)

Mar 8, 2021 - Phase 2 reopening 1594 cases (if it’s going back up wouldn’t you pause?)

Apr 7, 2021 - Phase 1 return cases over 5000

It is unclear whether the threshold is around 1600 or 5000, or what it is based on. Search did not turn up clear criteria.

Alberta predictably prevents itself from reaching zero covid by reopening & maintaining spread.

Some great articles about how the mitigation (maintaining spread) strategy compares to the zero covid strategy, and how the zero covid strategy is healthier for the economy. It also has shorter lockdowns which do not require masks once everything reopens – even the anti-maskers would be happy about this.

Canada Is One Big Pandemic Response Experiment.

It Proves ‘Zero COVID’ Is Best

Concludes major French study scanning nations

Those that chose to aggressively eliminate covid19 — China, Australia, Atlantic Canada and others — experienced less social and economic deterioration than those that didn’t.

https://thetyee.ca/News/2021/04/02/Canada-One-Big-Pandemic-Response-Experiment-Zero-COVID

Aiming for zero Covid-19 to ensure economic growth

Eliminating Covid-19 is the cheapest path towards economic recovery.

adopt an elimination strategy that is not solely based on vaccination.

China, Australia, Cambodia, Iceland, New Zealand, Taiwan, Vietnam, Japan, Korea, Laos, and Thailand have followed an elimination strategy.

The medical and economic arguments for an elimination strategy are overwhelming.

https://voxeu.org/article/aiming-zero-covid-19-ensure-economic-growth

Skiing after InternalBrace Ligament Augmentation

Posting this for the Snowheads ski forum thread

https://snowheads.com/ski-forum/viewtopic.php?t=130739

This is the first time I’ve went back to Lake Louise since being injured there. One of the reasons I wanted to go was to overcome any mental barrier remaining about skiing there.

This photo unintentionally has the ridge & shelf where it happened way in the background. I plan to get up there, but have been skiing with looser buckles to train through another problem I experience skiing which requires different runs that I would usually be on. Waiting for the next day it softens up to go back before the hill closes for the season.