Excellent write up repeating the pitfalls from basing decisions on ‘piece-price’ and failing to factor actual total cost of ownership – with some perspective from the international business community laughing at how North Americans miss this. It doesn’t seem to matter how often this is communicated, CFO’s and purchasing managers keep using inaccurate costs to base decisions on. However now that shipping costs are 10x higher, finance/accounting, purchasing will incur a greater loss for missing this – learn to calculate your total cost of ownership.

Key points from article:

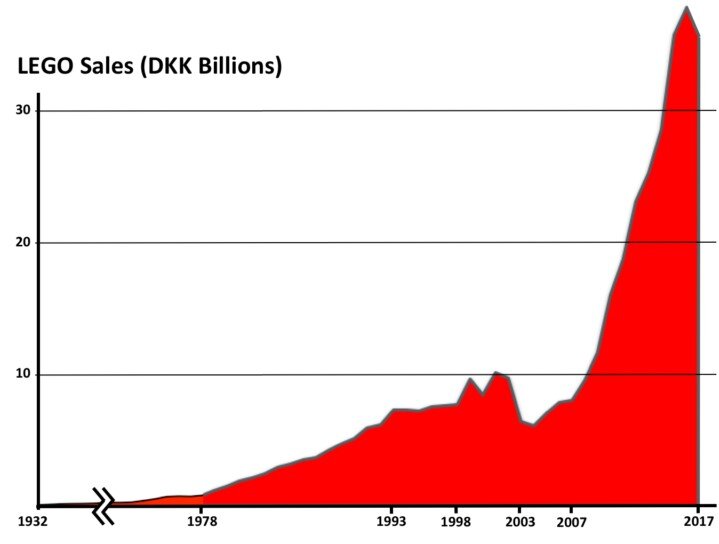

“The cost benefit to manufacturing in China just isn’t there anymore.”

“in the U.S., purchasing organizations are primarily fixed on obtaining the lowest “piece-price,” pretty much regardless of other factors.

When asked “why,” I responded that reduction in material was the primary metric used to judge and reward purchasing managers.

I was then again asked, “why?” My response was that material variance is a primary focus when U.S. corporate CFOs report their quarterly financial results to stock analysts where, by the way, total cost is seldom—if ever—mentioned.

I had to explain this several times, as most of the attendees were incredulous to the fact.”

“Most suppliers are geographically close to their customers” – *a JIT practice – “and so are more closely integrated with them than their western counterparts.”

“Total cost,” not “piece-price” is what is measured.

“Despite most of the attending companies having current or past business relations with American customers, most were completely unaware of how Americans viewed performance in its purchasing function.

It didn’t make sense to them, but did generate a few laughs”

“if honest total cost metrics are employed, the cost benefit to sourcing in China just isn’t there anymore.”

Harry Moser, Reshoring Initiative CEO, set up a total cost calculator CFO's can use to learn their Total Cost of Ownership Estimator available here https://www.reshorenow.org/tco-estimator

I’ve used this to calculate actual cost comparisons at more than one company and it typically is more economical to source locally – which also reduces sourcing from region typically supplying product high in defects, which increases lead times when you have to reorder to replace defective stock and let the customer know you won’t be on time. Local sourcing also reduces distance & associated lead times, a direct driver of sales and bottom line results.

*I can't recall a business that knew their actual cost of offshoring, do you know yours?