TOTAL Confirmed cases to date

NEW cases

ACTIVE cases to date

TOTAL Confirmed cases to date

NEW cases

ACTIVE cases to date

Washington State Liquor and Cannabis Board improves licensing process with Lean

Significantly reduced time to obtain license & eliminated 150-170 calls per month from frustrated customers. To zero

A look at improvements made by the Washington State Liquor and Cannabis Board to create a better, faster licensing process.

Washington Department of Social and Health Services

https://www.youtube.com/watch?v=bct_H8X7HoE&list=PUsuYgYm8vWyUNUfI3CMzuSQ

I will put together notes from this and have 2 more coming up.

quick draft of notes

3:20

6:00 need to know why

11:00 empathy for Governor; making the case

16:00 barriers at the senior level

17:50

26:00 your why must get in tune with what they believe

29:00

34:00 why biological imperative to lean

DSHS results

37:00 work environment

40:00 make supervisors ready; don’t know how to manage

41:00 strategic plans real, change

46:00 no action; alienation; visual communication

48:00 QU

getting to front line

48:30 until we’re ready – energy

49:00 Heirarchy

51:00 last 5% wasting 15%

52:00 QU

1st thing when you get back to office check in with them; they think you’re at a party; piña coladas Las Vegas

Share something you learned, that it’s about them, and they get to have a more active voice

Share strategic plan

54:00 but you have a stakeh

Squarespace is trying to figure out why embedding is not working but the link above should be ok for the interim

The Department of Social and Health Services is the State's largest agency with 2.2 million diverse clients including seniors, children, juvenile offenders, ...

Improved its transportation vehicle purchasing, resulting in $2.5million dollars cost avoidance in long-term vehicle replacement expense as well as achieving several other efficiency, environmental (cleaner air produced by reduced fuel emissions) and safety benefits. Read whole article pdf

2017 Strategic Lean Project Report link:

Improved the medical records process at the male offender intake prison Washington Corrections Center

WCC went from receiving 75 reports of quality issues down to 6 in a three month period.

The quality issues included missing overflow medical record volumes, and missing history, physical or problem sheets from medical records.

2014 article:

Washington's Department of Corrections staff says it's following the lead of companies like Toyota and Boeing in identifying more efficient ways to do business under what's known as lean strategy.

For example, they are saving $1.3 million a year in food expenses. Most of those savings are from streamlining menus across the state. By serving the same meals at the same time, the state is able to purchase ingredients in bulk, and therefore at cheaper prices.

November 1, 2011 article link:

also here:

http://sustainabilityinprisons.org/wp-content/uploads/2013/02/king5-prisons-go-lean1.pdf

Similar to the previous post of a paper I wrote years ago, this one was written years earlier in 2002.

It’s a review on how governments have created economies through legislation to profit off them, starting with the opium war in the 1800's continuing into modern times. The topic was decided on during summer course in 2002 for the requested assignment, I dug it up and see a few edits remain to be completed. A controversial topic. If there is enough interest I will edit & share paper.

Total Confirmed to date

NEW cases only to date

ACTIVE cases only to date

"Converting from a lean dreamer to a lean realist"

- several great business insights in this

https://www.lean.org/womack/DisplayObject.cfm?o=711

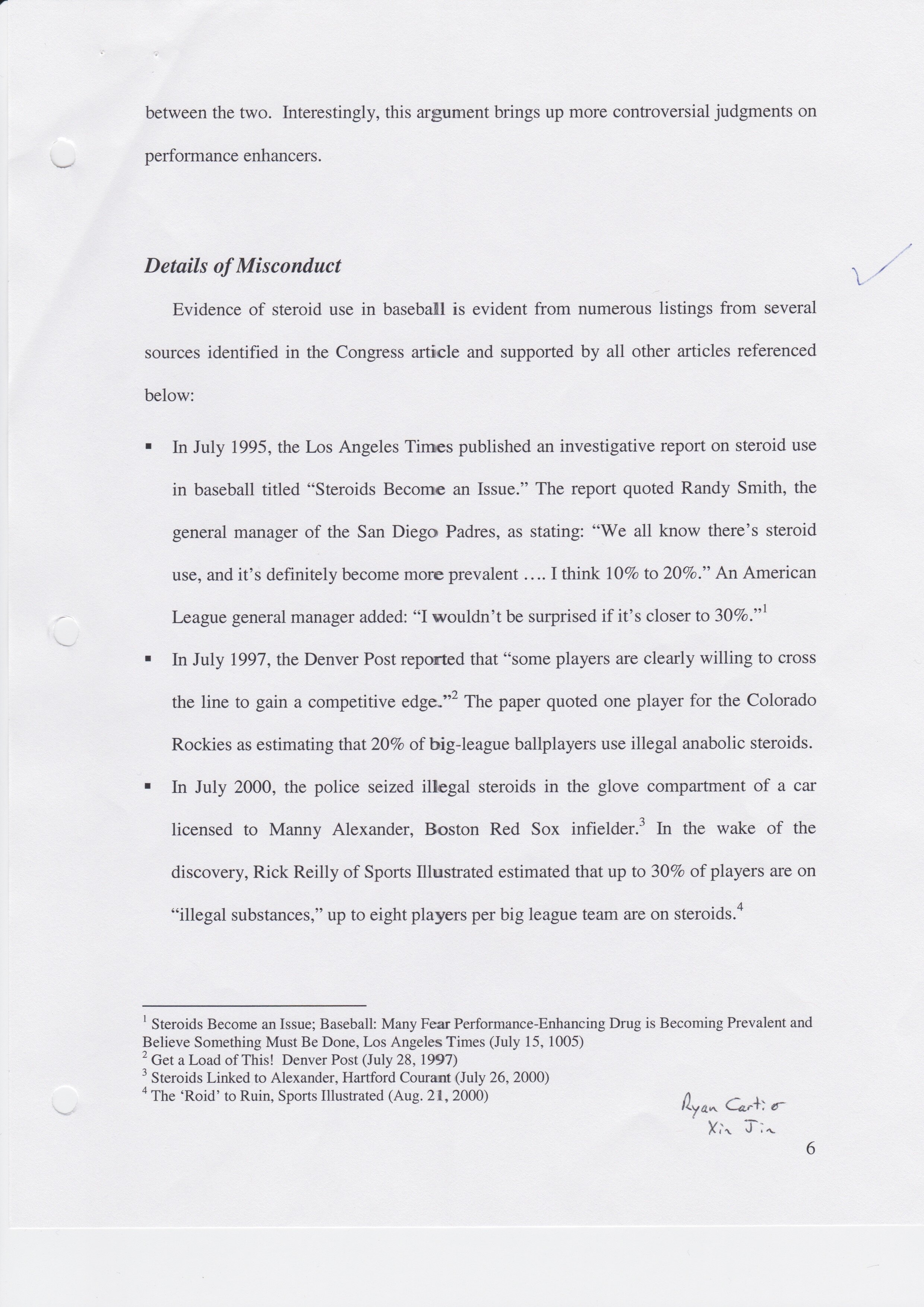

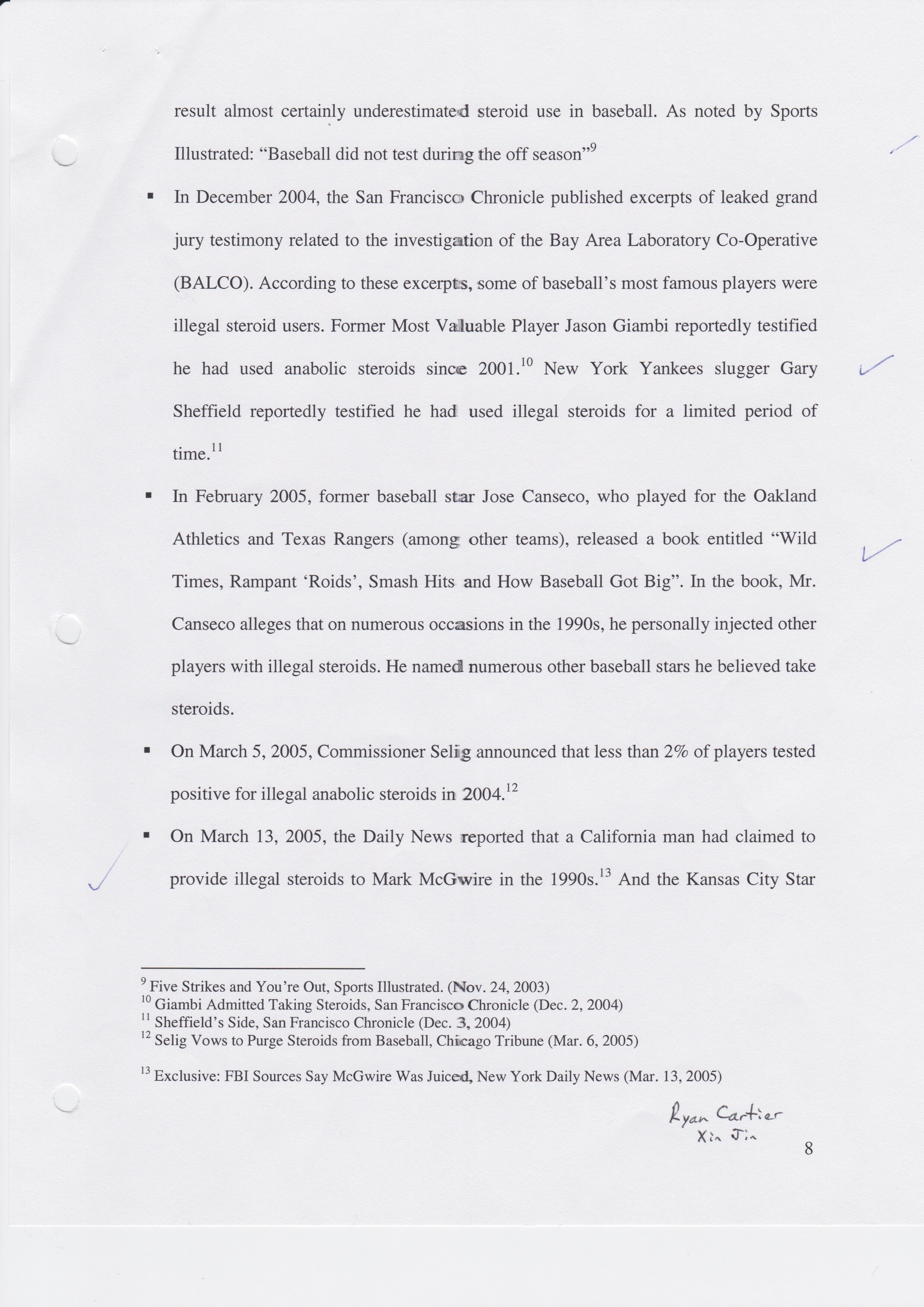

Business Ethics Assignment from Nov. 27, 2005 - decision to examine MLB (Major League Baseball) stance on steroids after deemed an illegal performance enhancer in North America, contrasted with laser eye surgery.

Authors: Ryan Cartier & Xin Jin.

I decided to scan & upload online. If there’s enough interest I’ll figure out how to upload the pdf and might have it typed up, let me know

Disclaimer:

I've been involved in sports and around athletes most of my life. It is a personal decision to use performance enhancements.

I am indifferent to someone else’s decision to use performance enhancements; I have known many who do and do not.

In the case an athlete decides to compete in a league where they have agreement or rules existing that performance enhancements are not to be used which they decide to accept, both the individual and the league should honour the criteria they have committed to.

I have a lot of notes from this, may post if requested; watch it twice

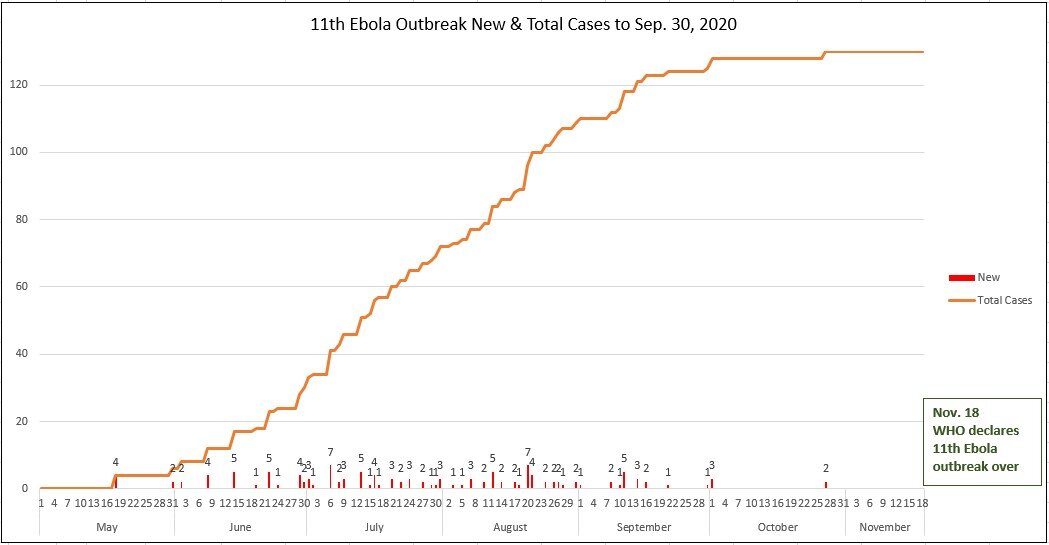

WHO (World Health Organization) declared current ebola outbreak over in Wangata Mbandaka region DRC. It started in May, a few months after the corona virus, and during the period in which the 10th outbreak in the eastern DRC was announced over. Stats:

130 cases (119 confirmed and 11 probable)

55 deaths (42.3% case-fatality rate)

75 recoveries.

According to the WHO, an Ebola outbreak is over when 42 days (twice the virus' incubation period) have passed since the last survivor tests positive.

Health officials will continue to watch for cases, as survivors can relapse and/or sexually transmit the virus for up to 6 months.

https://www.cidrap.umn.edu/news-perspective/2020/11/who-declares-end-drcs-11th-ebola-outbreak

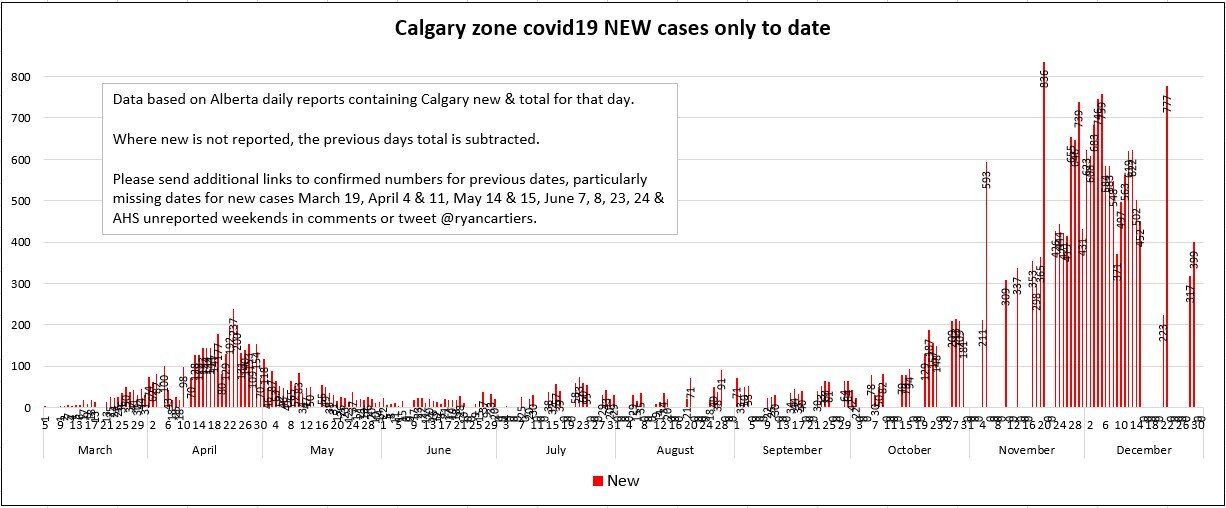

As I could not find any visual tracking, I continued maintaining this chart since my previous post:

Lean and the global Covid-19 vaccine race

Pall Corp. used lean product and process development (LPPD) principles to reduce normal 40 week development times down to 8 weeks.

update based on the daily numbers Alberta Health published:

Calgary Zone Covid19 TOTAL Confirmed cases:

Calgary zone covid19 NEW cases only to date

Calgary zone covid19 ACTIVE cases only to date

October increase has surpassed all previous numbers.

Another great write up by Karl Ohaus, link here:

https://www.linkedin.com/pulse/10-important-shifts-thinking-people-dont-talk-lean-karl-ohaus

key points:

‘teams try to “implement Lean” without making critical shifts in leadership thinking’

‘it requires leadership to shift their thinking to be able to benefit organizations at all.’

‘Every defect is an opportunity to learn.’

‘If you are too busy to acknowledge that something is a problem, then your organization will be right there with you’

Article link: https://planet-lean.com/a-lean-views-on-the-fight-against-climate-change

my notes/key points:

“The difficulty is compounded by the fact that most senior management are not looking for real, radical change. Most of the time, sadly but unsurprisingly, they’re seeking confirmation:

"tell me that what I’m doing is already lean.”

Leaders discover the way, others play catch-up, the world moves forward.

What lean really has to offer is not off-the-shelf pre-packaged solutions. Loving the package more than what is inside is the drama of the current zeitgeist.”

read the article twice:

my notes/key points from it:

“While they were pretty slow, way too expensive, and loved power point presentations, we did create our first couple of cells.”

“We even put potted plants in the first cell just to show how different the new look was.”

“We just did this because it made common sense.”

“These individuals were the real deal.”

“50 percent. Everything can be cut by 50 percent.” Later they told us they said 50 percent because they didn’t think we would want to hear the real number. We liked that as we were only thinking about 30 percent

“listen and learn. Don’t push back. We found right away that lean (Just-inTime back then) was “learn-by-doing” and we wanted to learn.”

“Mark helped us initially in finance by moving us away from standard cost accounting and toward something similar to what is now called lean accounting, and later became instrumental in creating/running the Danaher Business System (DBS). Switching to lean accounting was another big lesson as it allowed us to finally see what was going on and didn’t fight lean as standard cost accounting does. It also created great productivity in finance as Mark was able to go from 25 to 9 people and close the books in a day and a half.”

“all leaders need to emerge themselves in the details of lean and become lean experts themselves if they want to have a successful lean turnaround.”

“learning was the greatest strategic weapon we had ever seen.”

“cut your lead times from weeks to days, increase your productivity, drastically improve your quality and free up over half your floor space by removing the waste from your operations then you would have a huge strategic advantage.”

“A lot of times things didn’t work well at first (in fact most of the time) but we never let it go back to what it was. We just kept pushing till we solved the problems and made it work.”

“we involved the union in everything we did. We were always honest and up front with them. We treated them as equal partners.

we kept proving that every move we made was better for our work force we eventually formed a great relationship. We knew that the best ideas for removing the waste would come from the people doing the work, and that always proved to be true.”

“the Presidents of all 13 Danaher companies to be the lean drivers in their own companies. To do this we had to teach them lean… create the Presidents Kaizen.”

“all the Presidents to participate in a three-day kaizen every six weeks. They weren’t too happy about this at first but the gains we got every time were so big that this quickly changed.”

“Mark DeLuzio created the M&A integration process as well as the due diligence process as it related to DBS. And along with Larry Culp, Danaher CEO (and now the CEO of GE), developed the strategic planning process for all of Danaher”

David Belson’s letter to the Wall Street Journal in response to last week’s front page article about hospitals cutting costs and laying off staff. WSJ erroneously stated that efficiency caused a lack of being prepared for an emergency such as Covid-19. Noting how misleading this is, David wrote the WSJ.

They published his letter on Monday, shown here:

"Balancing the workload among different production lines led to a 19.3% increase in productivity

(we did invest some money in modernizing our equipment and improving processes)."

The management team of a Lithuanian mining company explains how they are transforming themselves to overcome resistance to business change.

- machine efficiency rate went up 20%.

Main mobile equipment used to shut down for planned maintenance every 150 hours, whereas today it does only every 250.

article here: https://planet-lean.com/fighting-resistance-lean-mining

No further replies from Alberta Health to my questions including why they stopped publishing weekend numbers, etc. Still waiting…

Here’s the update based on the numbers they published:

Calgary Zone Covid19 TOTAL Confirmed cases:

NEW cases only to date

ACTIVE cases only to date