Rebuilding Lego, Brick by Brick

How a supply chain transformation helped put the beloved toymaker back together again.

Aug 29, 2007

Issue 48 (originally published by Booz & Company)

these are my notes/key points, link below to full article, worth reading; also touches on how standardization drives creativity.

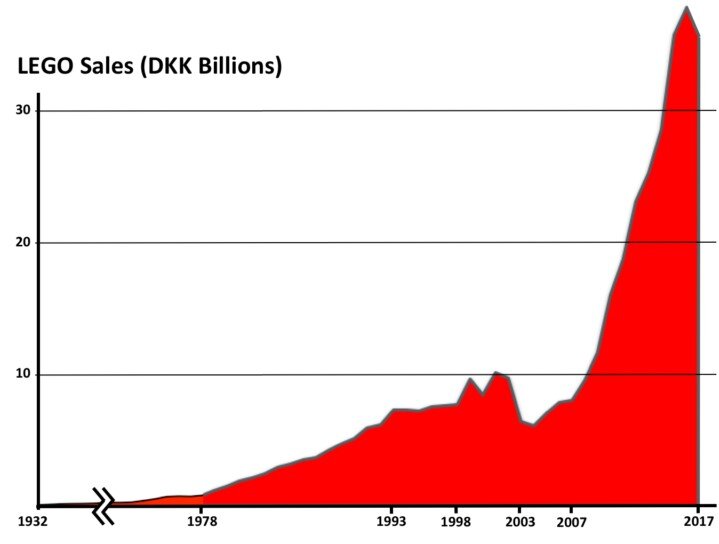

“The Lego Group had lost money four out of the seven years from 1998 through 2004. Sales dropped 30% in 2003 and 10% more in 2004, when profit margins stood at –30%. Lego Group executives estimated that the company was destroying €250,000 ($337,000) in value every day.

The Lego Group’s supply chain was at least 10 years out of date. Poor customer service and spotty availability of products were eroding the company’s franchise in key markets.

it took many years of underperformance before the company realized that the supply chain was a major source of its difficulties.

What made those problems especially hard to identify was that they grew out of the company’s core strengths: its capacity for innovation and its commitment to quality. Those were the very advantages that the company’s leaders had relied on.

Three-quarters of the Lego Group’s sales every year were from new, mostly nonelectronic products. “I believe that the focus on electronic competition was really a blame game,”

the “Kitchen,” the company’s product development lab

disregard for the costs of innovation. The company designers were dreaming up new toys without factoring in the price of materials or the costs of production. That kind of carefree creativity is unsustainable

where cost pressures are a constant concern.

did not align its supply chain with that business strategy.

teams placed their orders haphazardly and changed them frequently, preventing operations from piecing together a reliable picture of demand needs, supply capabilities, and inventory levels. This murkiness led to overall capacity utilization of just 70%.

such a fragmented system

Day-to-day operations were often chaotic. Operators routinely responded to last-minute demands, readily implementing costly changeovers.

rationalizing the cost of the company’s materials would be one of the easier parts of the transformation and would yield savings immediately.

Constraints don’t destroy creativity or product excellence, and they can even enhance them.

the perceived mandate had evolved into a crutch. “This idea had become an emotional concept and an excuse to oppose new cost-saving initiatives,” he says. “Anytime there was something someone didn’t want to do, they would say, ‘You cannot do that because of quality.’”

the Lego Group cut its resin costs in half and shrink its supplier roster by 80%.

the operational team put a process in place to help designers make more cost-effective choices.

Cost transparency gave developers a new way to define their achievement. “The best cooks are not the ones who have all the ingredients in front of them. They’re the ones who go into whatever kitchen and work with whatever they have,”

a new set of constraints could in fact enable them to become even more creative.”

also needed to move its distribution channels closer to the customer — and to lower its bloated distribution costs.

First, the number of its logistics providers was cut from 26 to three or four — enough to ensure resilience and gain greater economies of scale while still encouraging competition among the suppliers. This step alone saved more than 10% in transportation costs.

leapfrog the competition by redesigning its entire distribution system.

Although many companies have taken manufacturing to lower-cost markets and to contract providers, surprisingly few have done the same with distribution, although identical advantages exist. The Lego Group phased out five centers in Denmark, Germany, and France and created a single new center in the Czech Republic

- saved approximately €50 million ($67 million) since 2004, and forecasts savings in excess of €100 million ($135 million) over the next two years.

The tremendous gains in efficiency meant that despite the impact of rising oil prices on materials and transportation, stock turnover increased by 12 percent in 2005, and the same year, the Lego Group recorded its first profits — €61 million ($72 million) — since 2002. This positive trend further continued in 2006, with the Lego Group turnover up by 11 percent over 2005, and profits up by a staggering 240%

Addressing operations (streamlined product development, sourcing, manufacturing, and distribution) has allowed us to again focus on developing the business, on innovation, and on developing our organization to become a much more creative place to work”

https://www.strategy-business.com/article/07306?gko=813c3

The LEGO Group spells its trademarked brand name and its company name in uppercase letters.

(If you want to know the Lego co.’s origins: https://www.history.com/news/the-disastrous-backstory-behind-the-invention-of-lego-bricks)